Bottom Paint Basics

Knowing the different types of bottom paint and how they work makes choosing one easier.

It doesn’t matter whether you’re a power boater or a sailor; applying bottom paint to keep barnacles, slime, and other marine growth off your boat’s bottom is important preventive maintenance. Sure, it’s messy and tiring work, but doing the job yourself can save you money and give you the satisfaction of knowing the job was done well. It’s a task almost any do-it-yourselfer can accomplish during the course of a long weekend.

Boaters are faced with a myriad of choices when it comes to selecting bottom paint for their pride and joy. Photo by Gary Reich

Unfortunately, many boaters—even seasoned veterans—have lots of questions when it comes to choosing bottom paint for the season. The good news is that having a basic understanding of bottom paints and how they work make choosing the correct one easy.

Biocide Basics

All bottom paints contain and release some sort of toxic biocide that prevents critters such as barnacles and algae from hitching a ride on your boat’s bottom. Today, cuprous oxide (copper) is the most common biocide you’ll find in bottom paint, though some bottom paints contain cuprous thiocyanate or eco-friendly, barnacle-busting ingredients such as ECONEA and zinc omadine.

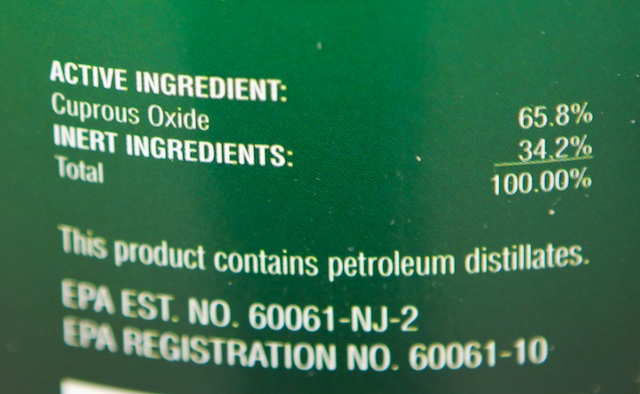

Generally speaking, the more biocide in the paint the better it will work, and you can look at the label of any bottom paint to find out how much biocide it contains. Some bottom paints also contain “slimicides,” which are designed to inhibit algae growth. Irgarol is one such bottom paint ingredient that controls slime, while Biolux is a trademark name for a slimicide used in Interlux bottom paints. Again, look on the paint can label for more information on how much of these ingredients are included in the paint.

Cuprous oxide is the biocide found in most bottom paint. You can check the paint can's label to see how much is in there. Photo by Gary Reich

Bottom Paint Types

There are all sorts of different bottom paints made up of a myriad of different ingredients and they’re all designed for all sorts of applications. How you use your boat and where you keep and run it will determine the bottom paint that has the potential to work best.

- Ablative Paints: Ablative bottom paints are much like a bar of soap in that they slowly wash away as your boat moves through the water, gradually exposing fresh layers of biocide throughout the boating season. Look for names such as Interlux Fiberglass Bottomkote ACT, Micron CSC, Pettit Ultima, or Hydrocoat. These paints are good for boaters that use their boats often, but are not as advantageous for folks who may not take their boat out more than a handful of times a season. They’re also popular for folks who boat in waters notorious for slime and algae growth.

- Modified-Epoxy Paints: Modified-epoxy paints are often called “hard paints,” because they continue to cure and get harder, even after the boat is launched. These paints slowly percolate a steady stream of biocide throughout the season, regardless of whether the boat is moving or not. This makes them a great choice for boats that may not leave the dock as much as others, but they’re also a good all-purpose paint. Top choices in this category include Coppercoat, Pettit Trinidad, or Interlux’s Ultra or Fiberglass Bottomkote.

- Hard Ablative Paints: These relatively new bottom paints offer boaters the advantages of both hard and ablative paints. They’re tougher and more abrasion resistant than typical ablative paints, but also have some self-polishing qualities. Interlux Fiberglass Bottomkote NT is one such hybrid.

- Vinyl Paints: The last group of bottom paints we’ll discuss are called “hard-vinyl.” These paints dry to an extremely hard, durable finish that’s tough enough to be burnished smooth, making them ideal for performance sailboats and powerboats. They’re also recommended for boats that live in and out of the water, such as those on a trailer or lift (or in a high-and-dry facility), because the hard finish resists damage from skids, floats, or trailer rollers. Interlux’s VC Offshore is a popular hard-vinyl bottom paint.

Interlux's Micron CSC is a good bet if you're looking for an ablative-type bottom paint. Photo by Gary Reich

Solvent-Based Versus Water-Based

The ingredients in bottom paints—pigments, biocides, binders, etc.—are typically suspended in a medium that is made of some sort of petroleum-based solvent such as mineral spirits. But with concerns over volatile organic compounds (VOCs—see “Environmental Concerns” below) and reservations about boat owners coming into contact with these toxic ingredients, more and more water-based bottom paints are hitting the market.

Besides the less-toxic nature of these paints, another upside to choosing a water-based bottom paint is the ease of cleanup. Instead of having to buy additional solvents and cleaners for application and cleanup, boat owners can simply use water. We also like the fact that these paints give off far fewer noxious-smelling fumes than their solvent-based counterparts, making the application process more tolerable.

Freshwater Versus Saltwater Paints

You might be wondering if you need to consider special bottom paint if you use your boat in fresh water, since most of the bottom paints we’re discussing here are primarily destined for use in salt-water environments. The answer to that question is both yes and no.

Since fresh water boats typically don’t have to deal with barnacle-like creatures—unless zebra mussels are an issue where you keep and use your boat—bottom paints with a low percentage of cuprous oxide are often just as effective as ones that are loaded with the stuff. Still, fresh water boats are way more susceptible to fouling by algae and slime than boats used in salt water.

That’s why we recommend that fresh water boaters use bottom paints with slime control additives such as Irgarol, Interlux’s Biolux, zinc pyrithione, zinc omadine, or Teflon. You’ll also want to consider using an ablative paint versus a modified-epoxy. If zebra mussels are an issue in your area, consider using bottom paint with a high percentage of cuprous oxide.

Paints for Metal Boats

If you’ve got a steel- or aluminum-hulled boat you likely know that you can’t simply slap on any old bottom paint, especially one containing cuprous oxide. Copper-based bottom paints interact with metal-hulled boats when immersed in water, causing galvanic corrosion that can result in serious damage to the hull.

Luckily there are bottom paints manufactured with biocides that do not react adversely with metal-bottomed boats. These paints typically contain the biocide cuprous thiocyanate instead of cuprous oxide. Two such paints include Interlux Trilux 33 and Pettit Vivid. Additionally, eco-friendly ECONEA-based, copper-free paints such as Pettit Ultima or Interlux Pacific Plus, can be used on metal boats.

Pettit's Trinidad is one of the best modified-epoxy bottom paints available on the market. Photo by Gary Reich.

Still, even fiberglass boat hulls have underwater metals attached or mounted to them that sometimes require antifouling paint—powerboats with aluminum outdrives immediately come to mind. Interlux manufactures a spray version of its Trilux 33 anti-fouling paint that we’ve had good luck with and Pettit’s Lumaspray also works well. Other underwater metal parts like shaft struts, rudders, keel shoes, and through hulls can also benefit from this paint, though bronze and stainless-steel are not particularly reactive with cuprous oxide bottom paints.

Environmental Concerns

The downside to biocides like cuprous oxide is that they aren’t entirely selective in what they poison, which means they have the potential to contaminate the water around them and harm fish, crabs, and other beneficial marine creatures. As a result, copper-based paints are increasingly coming under fire. A handful of local municipalities and the state of Washington have even legislated bans of copper-based bottom paints. Many more of these bans are expected to follow.

Addressing the toxicity of copper-based bottom paints, manufacturers have started introducing new, less toxic biocides into their bottom coatings. Among them are ECONEA and zinc omadine, which are usually used in conjunction. While some boaters might be skeptical of these new-fangled biocides, we’ve seen independent testing that shows these chemicals to be quite effective. Paints that use ECONEA and zinc omadine include Pettit Ultima Eco, Interlux Pacifica, and Sea Hawk Smart Solutions, among others. More paints with these new eco-friendly antifouling compounds are coming on the market with every boating season.

But biocides aren’t the only component in bottom paints that can harm the environment. They also contain VOCs, and high concentrations of these materials in the atmosphere have been shown to create air pollution. While the federal government regulates the density of these compounds in all paints, certain states and local municipalities have taken regulations even further, especially in California.

Bottom paint manufacturers respond to these regulations by introducing low-VOC paints to the market, most of which are water-based. Pettit’s Hydrocoat and Hyrdrocoat ECO, Interlux’s Fiberglass Bottomkote Aqua, and Sea Hawk’s Monterey are a few low-VOC bottom paints to consider, especially if you’re looking to up your eco-friendly game.

That’s a Wrap

Now that you know the different types of bottom paints and how they work, be sure to check in with a pro at your local marine supply shop to find out what their recommendations are for paints that work well in your area. Chances are they get a lot of feedback from other local boat owners on what brands work well for them. You’ll also want to find out if the paint you’re planning on applying is compatible with what’s already on the boat’s bottom, too. Here’s hoping your upcoming boating season is slime- and barnacle-free.

Read How to Paint a Boat and How to Prep a Boat for Painting to learn more about the job of actually preparing the bottom and applying the paint.

Editor's Note: This story was originally published on boats.com in April 2014 and updated in June 2016.